|

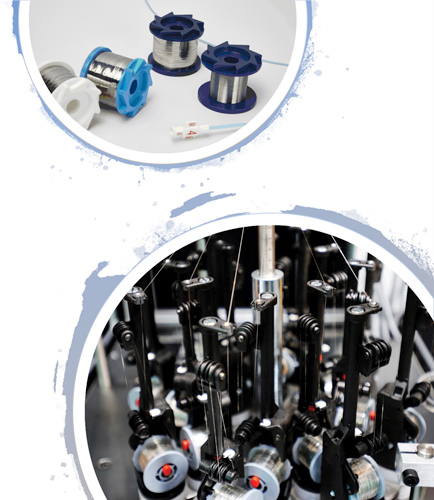

692 Plant Road, PO Box 619 Starting with rod or wire, and through the process of drawing, rolling and annealing, we produce flat and fine wire to your exacting and extreme dimensions. We have state of the art equipment that uses the latest in "on-line" gauging and data acquisition technology that generates full SPC reports. This enables you to have tolerances as tight as +/- .0001 (.0025mm) on our lightest gauges. |

|

High-Quality Alloys for Catheters of Any Shape and Size

|

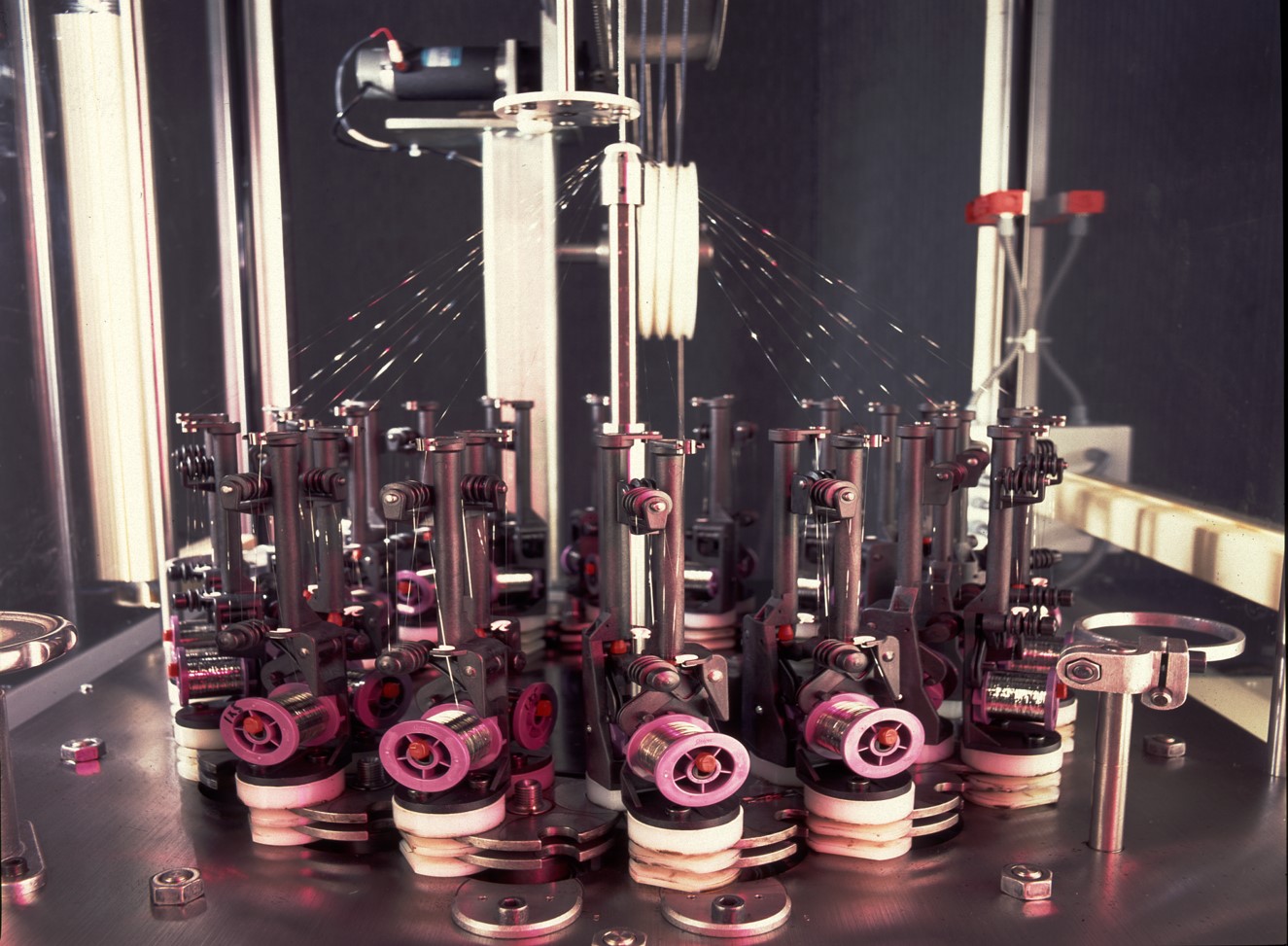

With serious medical consequences at hand, Ulbrich takes pride in providing medical device manufacturers with the metals they need to create supremely functional catheters. Combining our vast knowledge in R&D with accuracy and high-precision winding, we’re committed to giving you what you need to manufacture first-rate catheters for doctors and patients. And because we produce braid and coil reinforcement wire in various alloys, we’re experienced in making alloys that can be used in all types of catheter products, including braided catheters and shafts, coiled shafts, micro-catheters, EP catheters, vascular catheters, and more. Available Alloys:

|

|