|

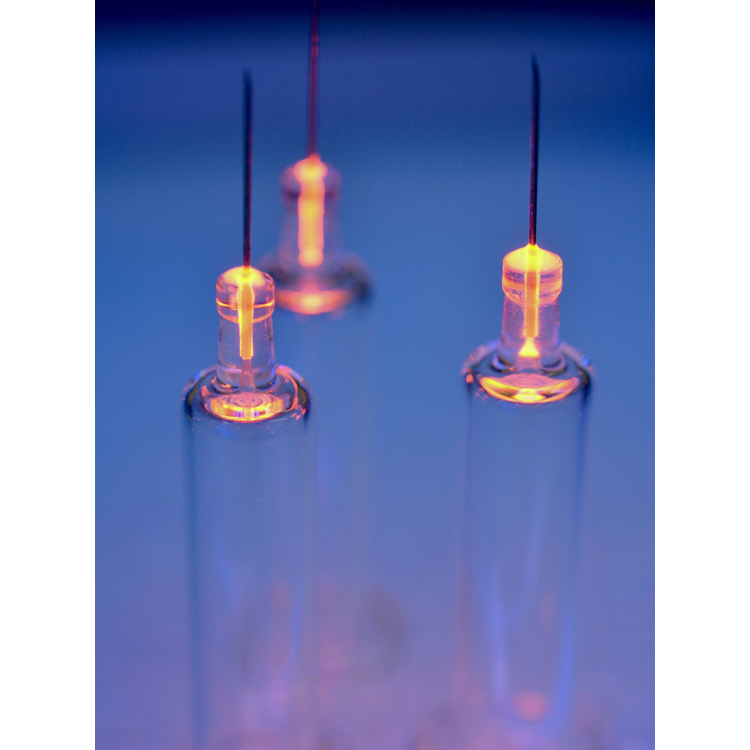

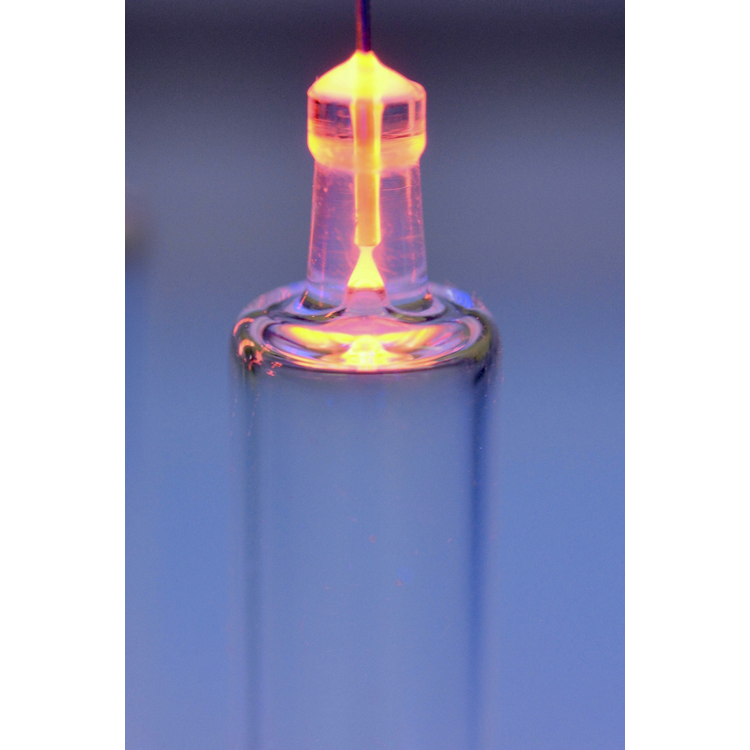

142 Industrial Lane MID (Minimally Invasive Device) Series Light Curable Adhesives Field failure is not an option, and that mandate resonates in every adhesive development project and with every product recommendation. Panacols’ adhesives for medical device assembly are specifically formulated to meet the critical performance and regulatory demands of this growing market. Beginning with raw material selection, Panacol-USA adhesives are designed and developed to provide superior adhesion after sterilization and aging, resist humidity and moisture, maintain lot-to-lot consistency, and fully crosslink upon cure to assure biocompatibility to USP Class VI and ISO 10993 standards. |

|

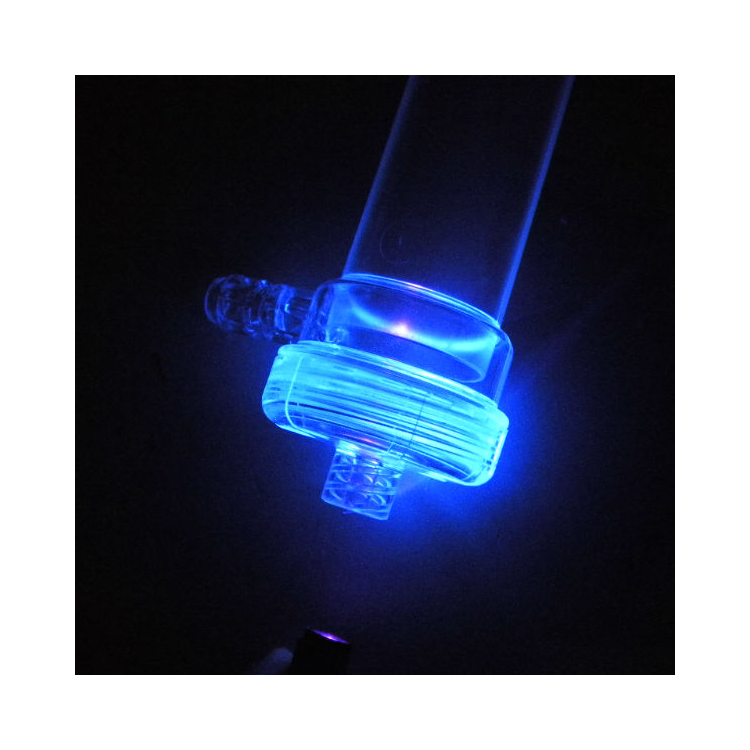

Cure-In-Place Gaskets

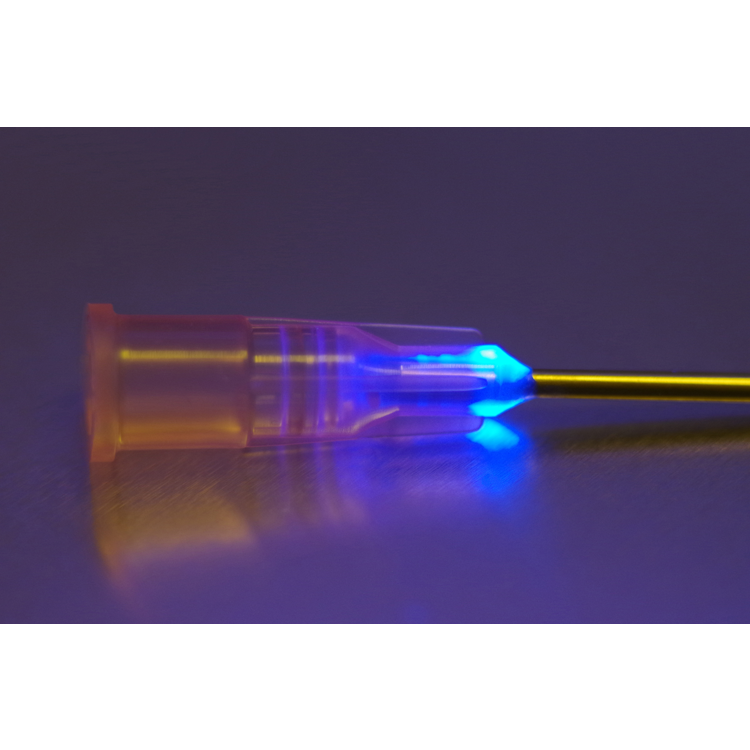

U V light curable Form In Place gaskets are dispensed as flowable liquids or non migrating gels, exactly where a gasket is required, and can be cured (hardened) in seconds as part of continuous in line production process. Panacol USA UV gaskets cure rapidly with UV or LED systems, permitting immediate handling and continuous production.

V light curable Form In Place gaskets are dispensed as flowable liquids or non migrating gels, exactly where a gasket is required, and can be cured (hardened) in seconds as part of continuous in line production process. Panacol USA UV gaskets cure rapidly with UV or LED systems, permitting immediate handling and continuous production.

New, UV and visible light curable Form In Place gaskets, (FIP/CIP), are available from Panacol USA that possess flexibility, resiliency, moisture resistance, and low compression set. High viscosity gel gaskets will maintain their profile from dispense through cure.

With performance that surpasses traditional die cut gaskets, Panacol USA gasket materials are dispensed as flowable liquids or non migrating gels, exactly where a gasket is required. The material can be cured (hardened) in seconds with broad spectrum UV lamps or LED systems (365nm/405nm) as part of a continuous in line production process. These gasket materials are ideally dispensed using industry standard, programmable robotic equipment. Automation maximizes processing speed and ensures consistent gasket profile and cure. Adjustments for new product geometries can be made in minutes without the added costs, delays, and down time waiting for new (die cut) tooling. Gaskets can be formed on the spot for the most complex component configurations.

Panacol USA’s Stay In Place gasket technology produces gasket materials that adhere to the surfaces they are cured upon, allowing immediate handling and continuous production. In the event that future component disassembly and gasket replacement becomes necessary, the gasket can be removed without difficulty. A wide variety of gasket materials are available to meet desired functional performance. Typical performance properties include high resistance to moisture, low shrinkage, ability to withstand repeated thermal cycling, high cohesive strength, and surfaces that range from tack free to sticky (similar to a Pressure Sensitive Adhesive).

These products cure in seconds when exposed to UV/Visible light (320 460nm), with at least 50 mW /cm2 intensity. Panacol USA UV gaskets are also available that cure with LED system producing either 365nm or 405nm wavelengths.

View the light curable gasket products listed below for a possible candidate for your application. Please contact Panacol USA to confirm your product selection and to secure additional application assistance, including samples and process recommendations. In the event that these standard products do not satisfactorily address your performance requirements, Panacol USA will investigate other solutions that include development of gasket material that is specifically tailored to the complexity of your application.

Browse Panacol-USA Technical Documents for Product Details and Specifications