|

142 Industrial Lane MID (Minimally Invasive Device) Series Light Curable Adhesives Field failure is not an option, and that mandate resonates in every adhesive development project and with every product recommendation. Panacols’ adhesives for medical device assembly are specifically formulated to meet the critical performance and regulatory demands of this growing market. Beginning with raw material selection, Panacol-USA adhesives are designed and developed to provide superior adhesion after sterilization and aging, resist humidity and moisture, maintain lot-to-lot consistency, and fully crosslink upon cure to assure biocompatibility to USP Class VI and ISO 10993 standards. |

|

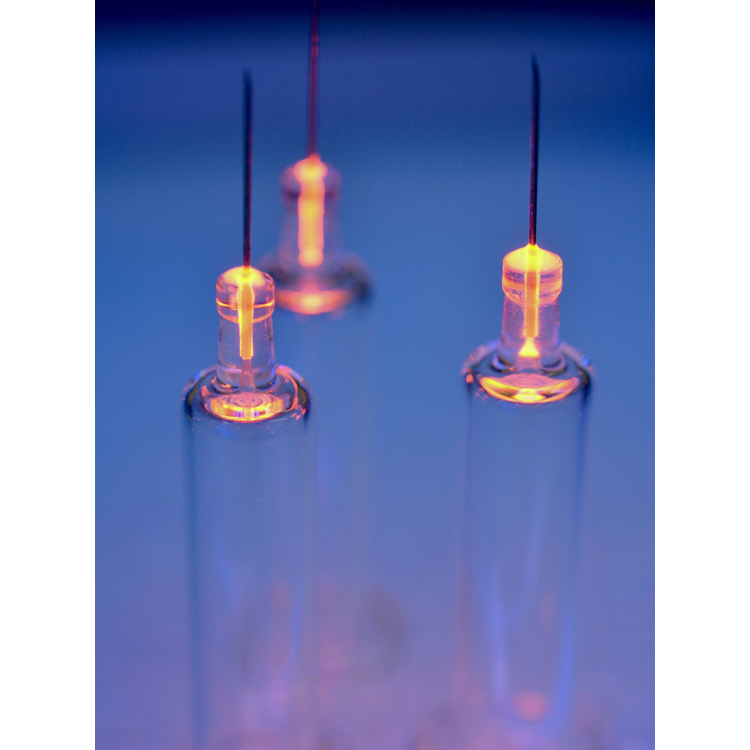

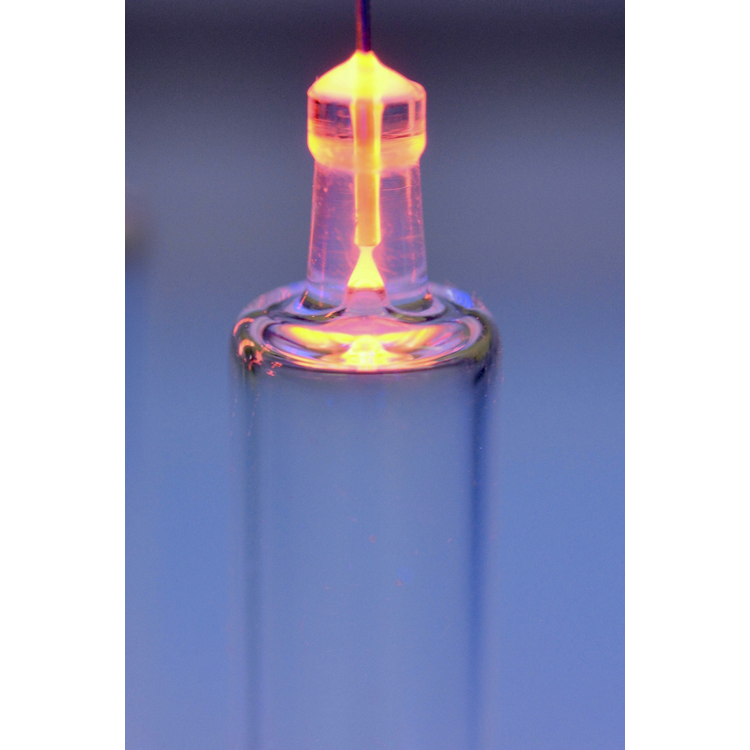

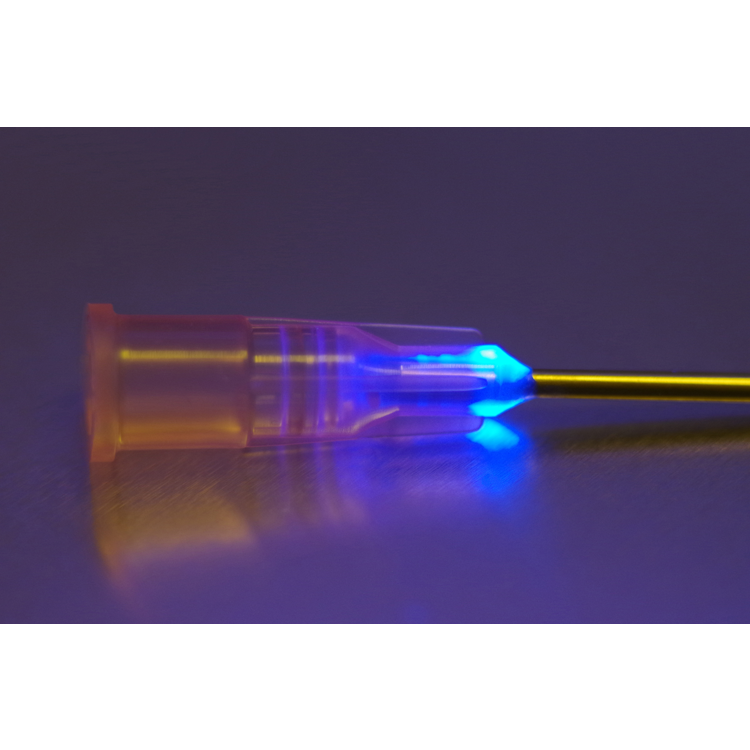

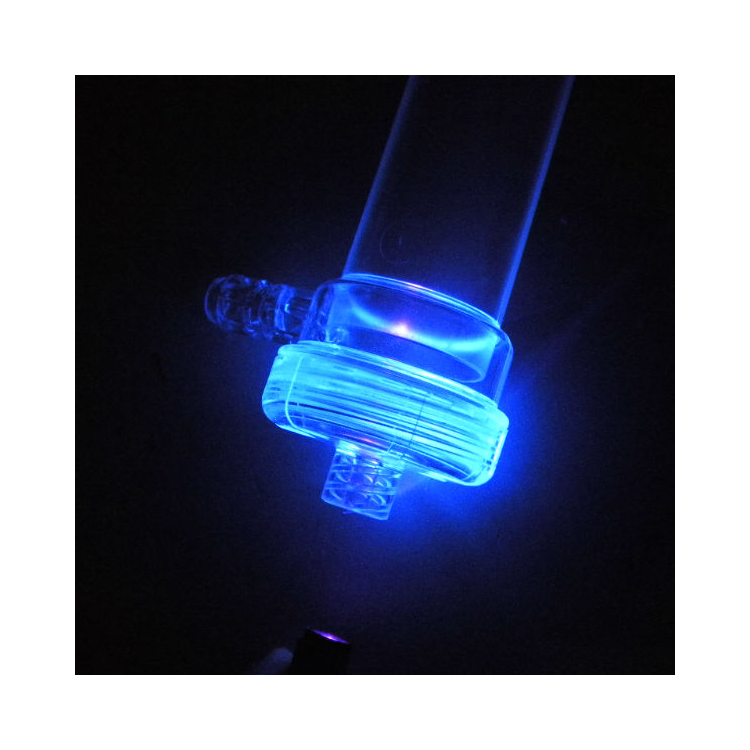

Needle / Syringe Assembly

Panacol-USA has developed a series of LED light curable adhesives that are ideally suited for bonding stainless steel cannula into hubs of various substrates and configurations. Panacol-USA’s LEDcurefamily of adhesives are products that fully cure in fractions of a second under low intensity UV/visible or visible light. This provides manufacturers with the ability to select more economical curing systems for their assembly process, including those based on LED technology.

Panacol-USA has developed a series of LED light curable adhesives that are ideally suited for bonding stainless steel cannula into hubs of various substrates and configurations. Panacol-USA’s LEDcurefamily of adhesives are products that fully cure in fractions of a second under low intensity UV/visible or visible light. This provides manufacturers with the ability to select more economical curing systems for their assembly process, including those based on LED technology.

Each Panacol-USA adhesive is typically available in several viscosity ranges to better match manufacturers’ hub designs and process requirements. Product specific viscosities can also be developed to optimize dispense/cure cycles involving unique hub and well configurations. Panacol-USA adhesives are moisture resistant, and when fully cured, possess dry, tack-free surfaces. The adhesives are specifically formulated to meet USP Class VI and ISO 10993 biocompatibility standards, and are compatible with gamma, EtO, peroxide plasma, and E-Beam sterilization processes. Autoclave sterilization may be possible in limited applications.

Panacol-USA’s needle and syringe assembly adhesives create high strength bonds that deliver consistent performance after sterilization and aging. To achieve maximum pull-strength with hubs molded from low surface energy polymers such as polyethylene and polypropylene, it isnecessary to apply surface pre-treatment (corona, plasma, etc.), and/or incorporate annular rings in the hub inner well diameter.

These adhesives are ideal for the high volume production of disposable hypodermic needles, syringes, safety syringes, pen needles, winged infusion sets, and biopsy needles. Solvent-free and single component, Panacol-USA medical device adhesives can be easily and precisely dispensed through stainless steel valves commonly used in device assembly processes. Fluorescing versions of each adhesive are available to enhance automated detection systems that monitor adhesive volume and profile.

View the needle/syringe assembly adhesives listed below for a possible candidate for your application. Please contact Panacol-USA to confirm your product selection and to secure additional application assistance, including samples and process recommendations. In the event that these standard products do not satisfactorily address your performance requirements, Panacol-USA will investigate other solutions that include development of adhesive specifically tailored to the complexity of your application.

Browse Panacol-USA Technical Documents for Product Details and Specifications