|

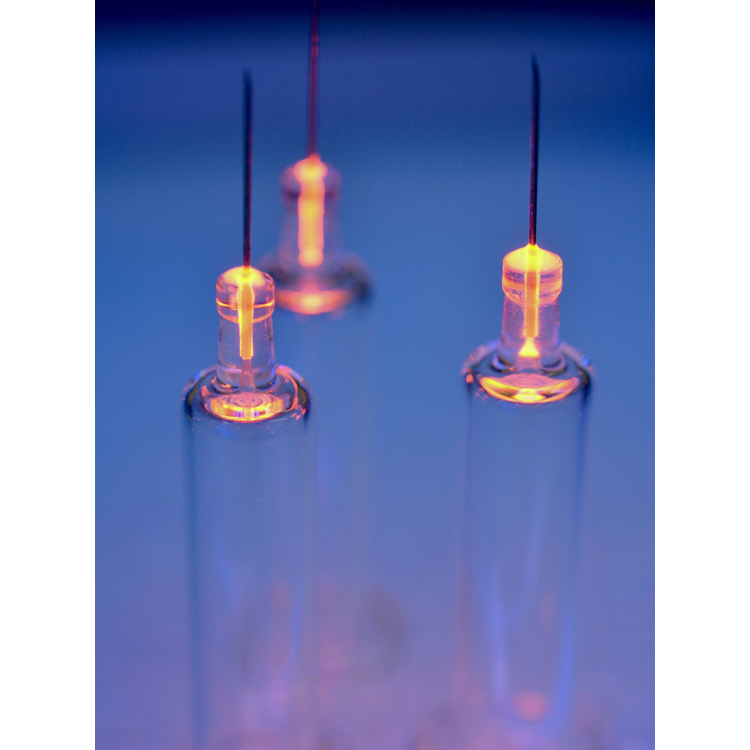

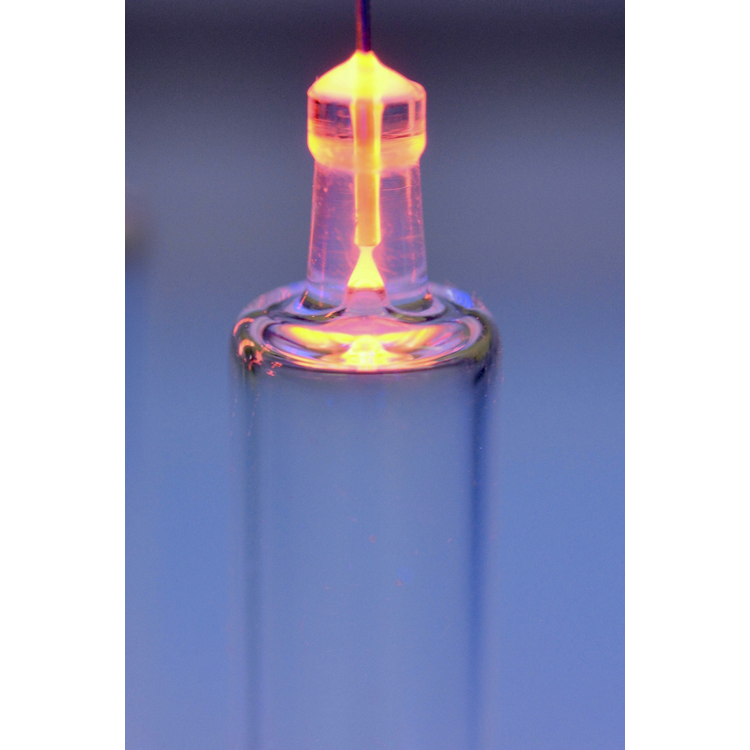

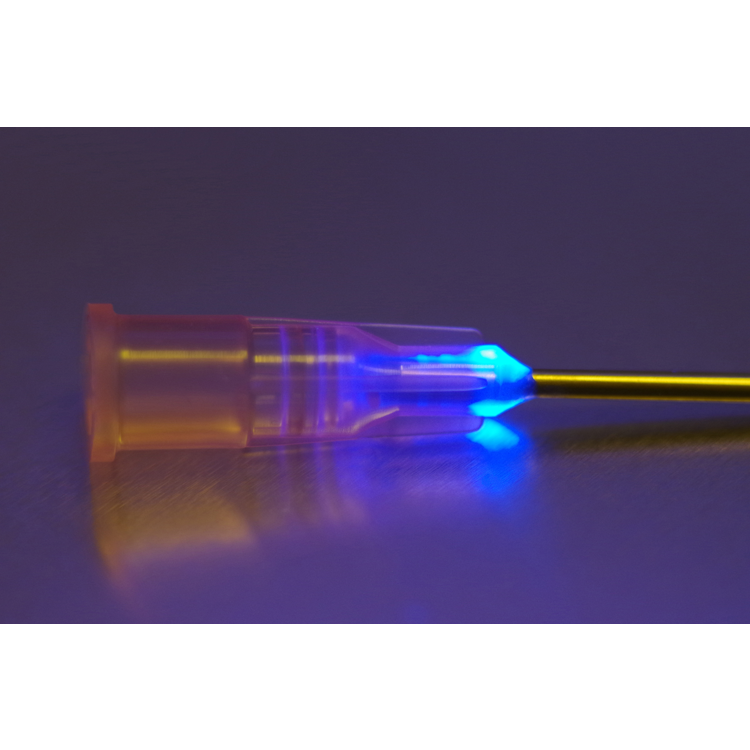

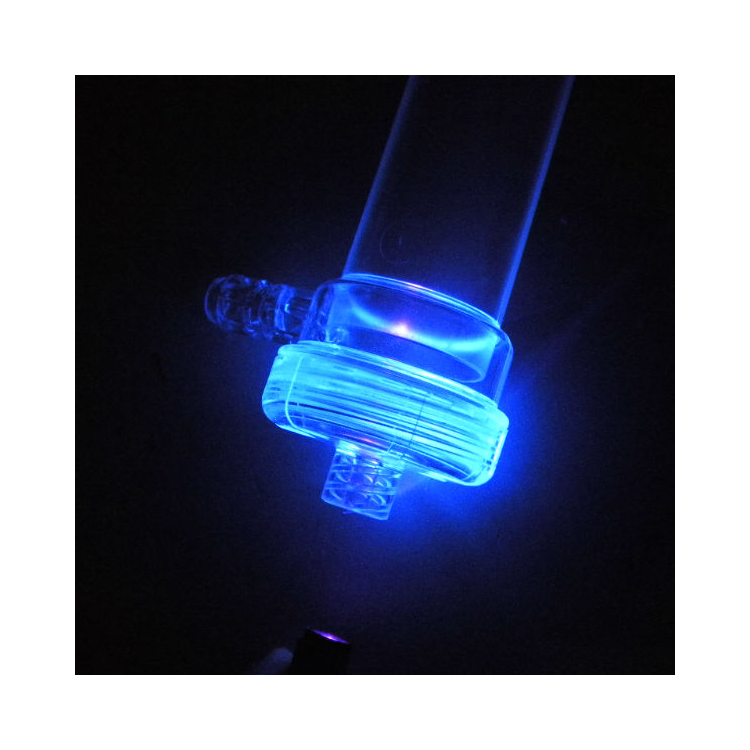

142 Industrial Lane MID (Minimally Invasive Device) Series Light Curable Adhesives Field failure is not an option, and that mandate resonates in every adhesive development project and with every product recommendation. Panacols’ adhesives for medical device assembly are specifically formulated to meet the critical performance and regulatory demands of this growing market. Beginning with raw material selection, Panacol-USA adhesives are designed and developed to provide superior adhesion after sterilization and aging, resist humidity and moisture, maintain lot-to-lot consistency, and fully crosslink upon cure to assure biocompatibility to USP Class VI and ISO 10993 standards. |

|

Room Temp & Thermal Cure Epoxies

Epoxies continue to evolve and improve. New single and two-component epoxy introductions are stronger, faster curing, and easier to work with. As an alternative to light curable adhesives, epoxies overcome challenges presented by shadowed bond lines and opaque substrates. They exhibit minimal shrinkage, and offer superior chemical and environmental resistance. Their non-photonic curing mechanisms allow them to be opaque in color, and they can be filled with thermally and electrically conductive materials.

Epoxies continue to evolve and improve. New single and two-component epoxy introductions are stronger, faster curing, and easier to work with. As an alternative to light curable adhesives, epoxies overcome challenges presented by shadowed bond lines and opaque substrates. They exhibit minimal shrinkage, and offer superior chemical and environmental resistance. Their non-photonic curing mechanisms allow them to be opaque in color, and they can be filled with thermally and electrically conductive materials.

As their exclusive distributor for the Americas, Panacol-USA offers room temperature and thermally curable epoxies from Panacol-Elosol. With an expertise in epoxy development, Panacol-ElosolGmbH is part of the Honle Group headquartered in Germany. They have been formulating and manufacturing adhesives for over 30 years. Panacol epoxies are packaged under the brand names of Structalit® and Elecolit®.

Structalit® epoxies are high performance adhesives, delivering superior strength, thermal stability, and chemical resistance. The epoxies form incredibly high strength structural bonds that are demanded in panel assembly, frame attachment, and ferrite bonding. In addition, select products are ideal for sealing and encapsulating (glob top) electronic and electrical components such as smart cards. They are also ideal for potting and casting applications. Structalit® products are available as single component or two component systems. The single component adhesives offer easy dispensing and fast, thermal curing. Two-component epoxy systems can be cured at room temperature or accelerated with heat. Various pot-life schedules are available to accommodate the infinite number of global production processes.

Elecolit® epoxies combine thermal and electrical conductivity with excellent bond strength. The electrically conductive epoxies are ideal for antenna printing, die bonding, and other electronic assembly associated with PCB, FPC, and LCD production. The thermally conductive epoxies facilitate heat transfer, and are typically used to affix heat sinks and power modules.

Electrical conductivity is typically achieved by filling the adhesive with metallic materials such as gold, silver, or nickel. Metallic fillers also offer the best thermal conductivity, which enables the electrically conductive epoxies to serve a dual function. However, if thermal conductivity is required without the possibility of electrical conductivity, Elecolit® offers epoxies containing non-metallic fillers. Elecolitconductive epoxies are available as one or two component systems.

View the Structalit® and Elecolit® epoxy products listed below for a possible candidate for your application. Please contact Panacol-USA to confirm your product selection and to secure additional application assistance, including samples and process recommendations. In the event that these standard products do not satisfactorily address your performance requirements, Panacol-USA will investigate other solutions that include development of adhesive specifically tailored to the complexity of your application.

Browse Panacol-USA Technical Documents for Product Details and Specifications